Primarily influenced by the automotive standard, our quality plan during the process of producing any new product usually includes the following key elements:

- Analysis of potential risks (FMEA)

- Creation of the operating procedure

- Inspection plan

- Partnership with suppliers

- Study of process capabilities

(Cmk, Cpk)

- Measurement System Analysis (MSA)

- Monitoring production using SPC control charts

- Preventive equipment maintenance

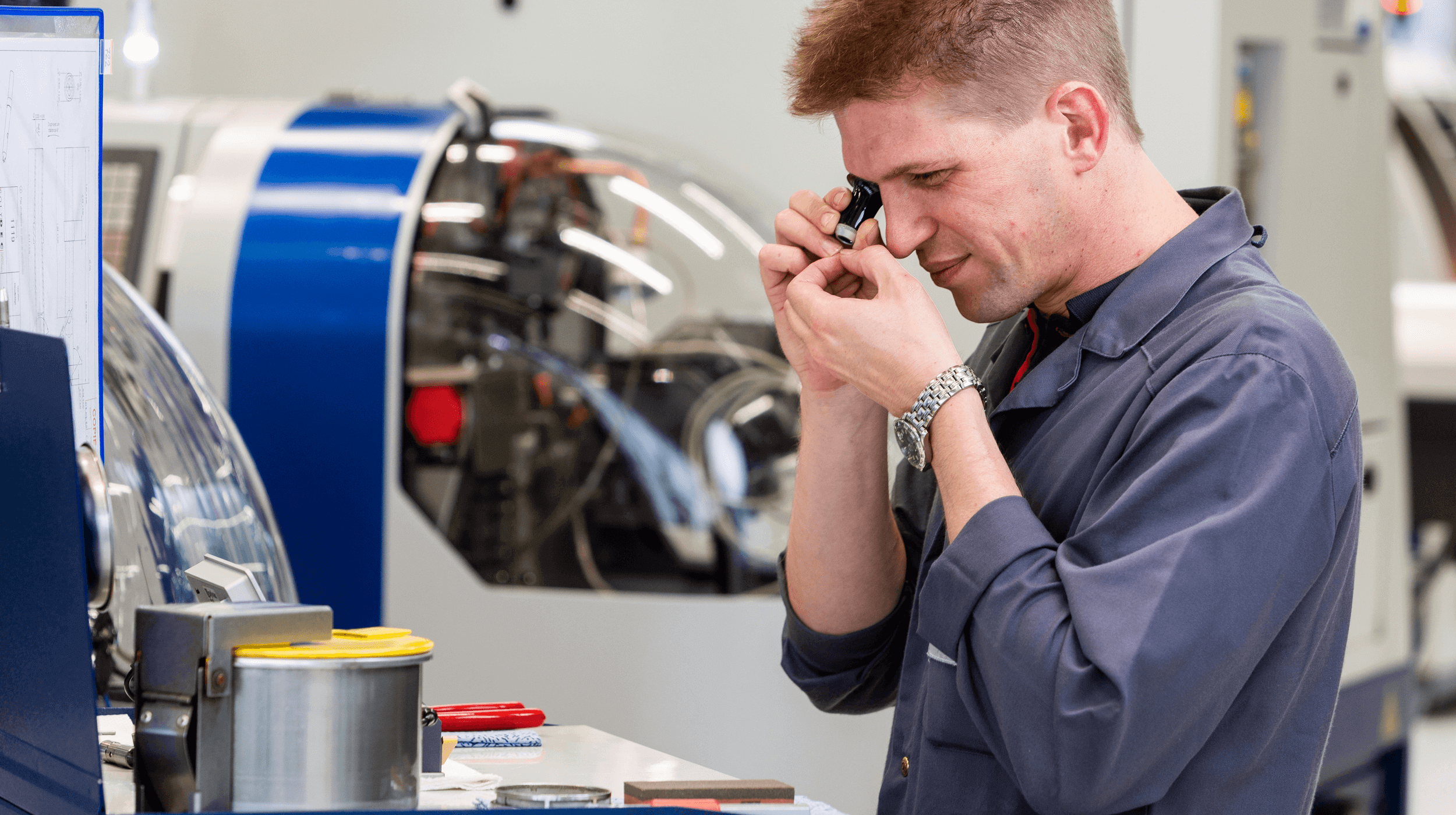

- Final product check performed by a qualified staff member

- PLCs working on the measuring principle using cameras or a probe; in some cases, the rate of the results can be as low as 0 ppm (zero faults per million parts)

- The 8D ("Eight Disciplines") method for handling non-conformities

The full quality plan and all the associated tests are collated to create a validation file. These documents are mandatory in the automotive and medical industries (PPAP) and must be validated by the customer before starting any series production.